44 electrical panel labeling standards

NEC Changes Part I: Required on Electrical Disconnect Label Anything beyond a visible conduit to a local load indicates a clear cut need for proper labeling of the disconnect. The "identification of the source that supplies the disconnecting means" is a critical addition to the 2020 NEC. For ALL disconnects, the associated power supply must now be clearly indicated on a label that is legible and clear! UL 969 Labeling and Marking: Standards, Requirements, More 26.07.2022 · Additionally, UL 969 Standards for Marking and Labeling cover pressure-sensitive, heat-activated, or solvent-activated adhesive labels that may contain text or pictographs. The requirements in UL 969 cover unprinted materials such as blank label stocks, overlaminations, laminating adhesives, and screen-printable adhesives that will become finished labels.

Wiring Color Codes - NEC Electrical Standards & 3-Phase It’s safe. And, it’s designed to take the guesswork out of electrical work. But it wasn’t always this way. A brief history of wiring color codes. It took until 1928 for wire color coding to make its debut. The National Electrical Code® (NEC) was the first to reference it, and today continues to set the standards for the electrical ...

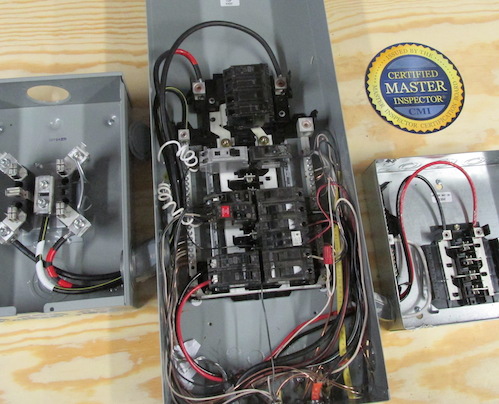

:max_bytes(150000):strip_icc()/how-to-wire-an-electrical-panel-1152762-11-ce4617ba201648959f532163cf32b8c6.jpg)

Electrical panel labeling standards

How Much Does It Cost to Replace or Upgrade an Electrical Panel… 11.02.2022 · The cost to relocate an electrical panel starts at around $1,000 but can go as high as $4,000 if a lot of rewiring must be done to accommodate the move. Cost to Rewire an Electrical Panel . Homeowners may not have much insight into whether the wiring of an electrical panel is in poor condition. If there is fire damage, melting, or obvious ... 1910.303 - Occupational Safety and Health Administration Listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling. 1910.303(b)(3) Insulation integrity. Completed wiring installations shall be free from short circuits and from grounds other than those required or permitted by this subpart. 1910.303(b)(4) › 2021/04/20 › necNEC + OSHA Electrical Panel Clearance Requirements In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36'' of clearance around it. Panels with 151 to 600 volts should have 42'' of clearance around it. This NEC working clearance will provide not only the person working on the equipment with room, but also their tools.

Electrical panel labeling standards. PDF Electrical Panel Requirements - Wisconsin Healthcare Engineering ... Electrical Panel Requirements 22 1. Electrical Panel Requirements (Labeling, Clearances, Protection, Act) 2. Other Electrical Code Citations (Extension Cords & Power Strips, Open Boxes, Fire Stopping, Arc Flash) © 2020 LLSC Heather Lauzon Werner 23 Labeling © 2020 LLSC Overcurrent devices or disconnecting devices: OCWR - Electrical Panel Safety For equipment operating at 600 volts, nominal or less to ground, electrical panels must have a minimum of three feet of clearance in front of the panel and a minimum clearance width of 2.5 feet or the width of the equipment, whichever is greater. PDF Electrical Panel and Circuits, Marking - ResponsibleAg The markings must be of sufficient durability to withstand the environment involved. 29 CFR 1910.303(f) - All panel board circuits must be identified on the face or inside of the panel door. Each disconnecting means for motors and appliances must be legibly marked to indicate its purpose, unless located and arranged so the purpose is evident. NEC 408.4 (A) panel requirements | Mike Holt's Forum The contractor is insisting that the distribution panels do not require proper labeling of any form as outlined in NEC 408.4 (A). They are maintaining that since the panel and breaker #s are being field labeled at the machine or connecting junction, the NEC 408.4 (A) provisions no longer apply.

› blog › everything-you-need-toComplete Guide to Electrical Panel Labels - Metalphoto Of ... Jul 25, 2022 · There are four sets of standards used within the United States that directly address electrical panel labeling in some way. These regulations are monitored and communicated by the Occupational Safety and Health Administration (OSHA), American National Standards Institute (ANSI), National Electrical Code (NEC), and the National Fire Protection Association (NFPA). If your industrial control panel is installed at the point of entry for the electrical supply circuit, the panel must be marked "Service Entrance Equipment" per the International Electrotechnical Commission (IEC) "EN Standard EN60 204-1 (2)" and NEC Art. 409. Electrical Panel Location and Installation: Clearance, Bathrooms ... 31.05.2021 · Electrical panels need to be installed 4′ off the ground with the center grip handle of the highest circuit breaker is no more than 6’7″ high to be NEC compliant. The clearance around the electric panel must be at least 30 inches wide with 3′ of front workspace clearance. A related requirement is NEC 210.5 (C) (3), which defines the labeling of conductors originating within each branch circuit panelboard or similar branch circuit distribution equipment. The wires need to either be color coded or marked with color-coded labels. Example: A = black, B = red, and C = blue (neutral is white)

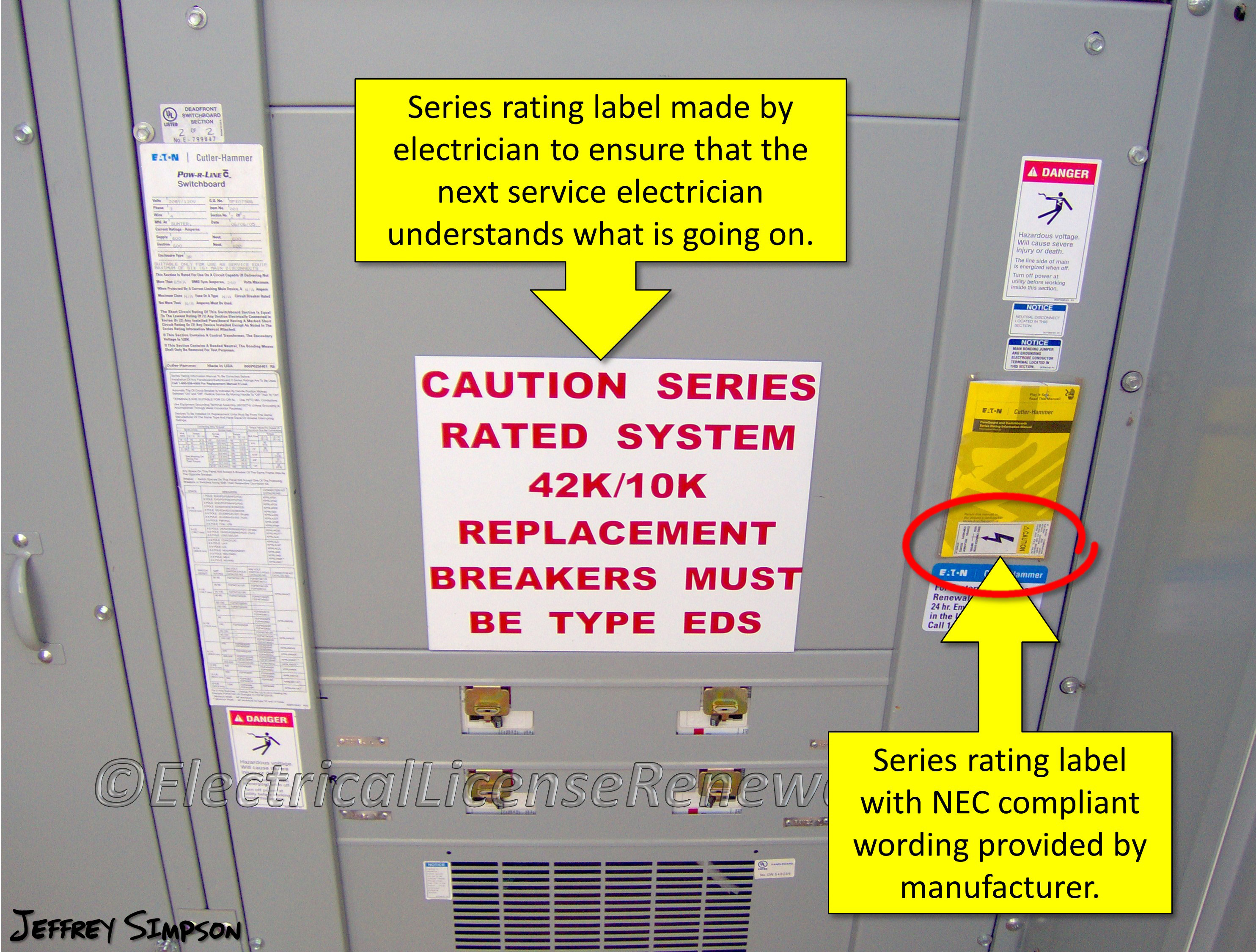

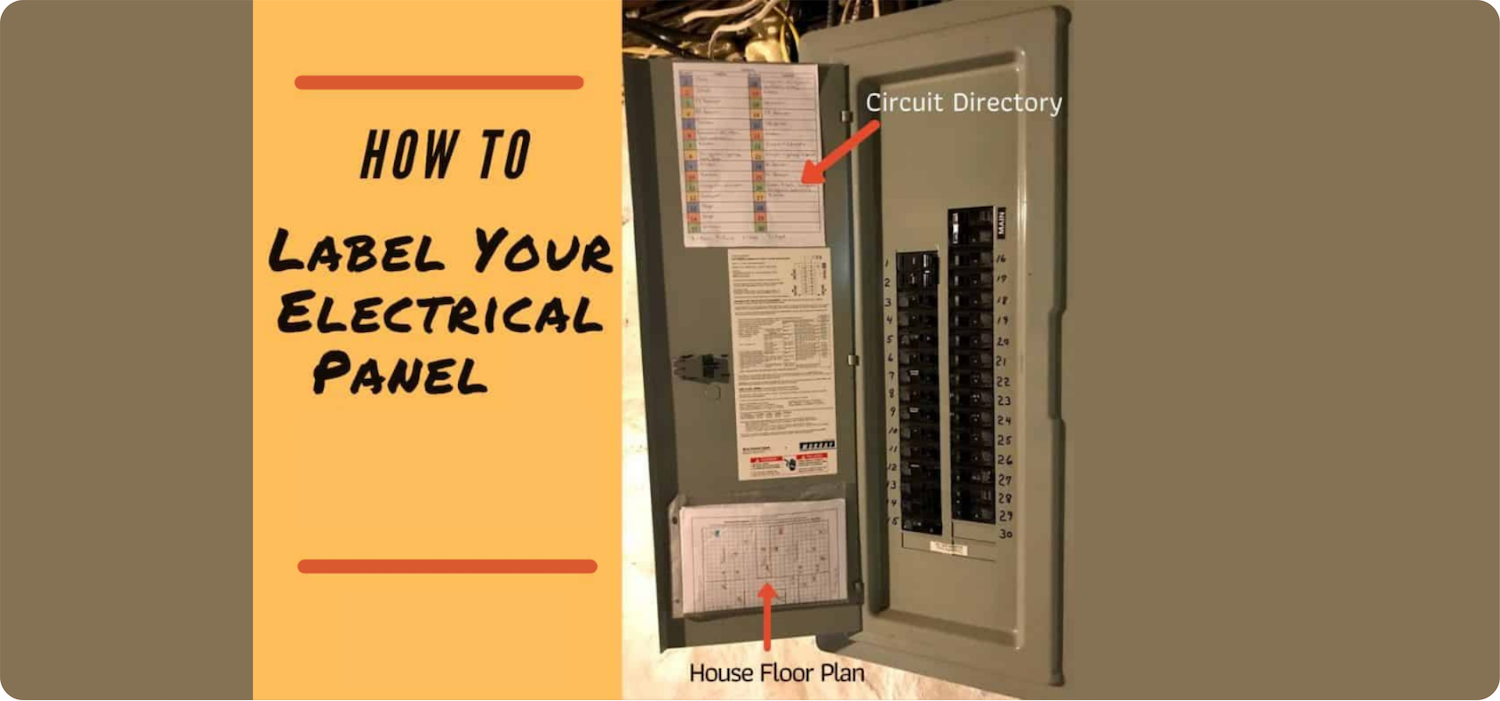

How to label properly? | Electrician Talk Label the panels from top to bottom. Odds on the left (1,3,5,7......). Evens on the right (2,4,6,8....). Label the conductors at their termination point in the field the same using number tags. In residential, if there are tandem breakers, they are A&B for each corresponding breaker space. Electrical - Standards - Occupational Safety and Health Administration 70E, Standard for Electrical Safety in the Workplace; Department of Labor logo. UNITED STATES DEPARTMENT OF LABOR Occupational Safety & Health Administration. 200 Constitution Ave NW. Washington, DC 20210. 800-321-6742 (OSHA) TTY . . Federal Government. White House; Electrical Panel Labels | Family Handyman The identification must be included in a circuit directory that is located on the face or inside of the panel door. The circuit directory must be durable enough to withstand the environment in which it is located. Each label identification must contain a degree of detail that distinguishes it from all other circuits. Service Equipment Labeling — NEC 2017 110.16(B) Figure 1. Arc flash hazard warning label as required by 110.16 (A) of NEC 2017. NEC 2017 introduced the new first level subdivision 110.16 (B) Service Equipment. This new addition applies only to service equipment rated 1200 amps or more. Note that this is the rating of the equipment, not the rating of the OCPD protecting the service equipment.

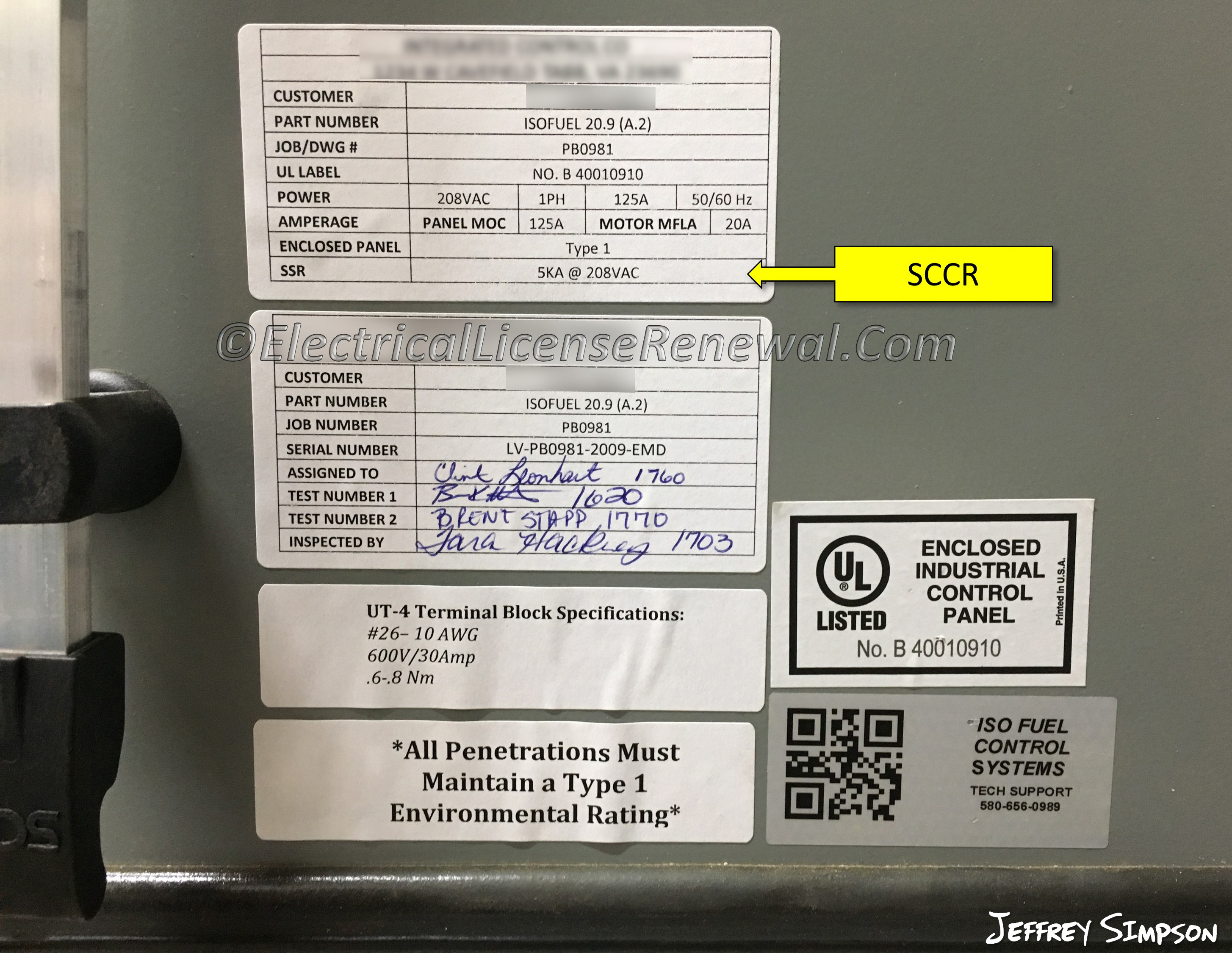

Strategies for electrical labeling and documentation NFPA 79-2015: Electrical Standard for Industrial Machinery, Article 700.5 (E), requires labeling of panel short-circuit current rating (SCCR) based on OCPD settings used. Periodic review of existing OCPD settings is a good idea to maintain a safe electrical system.

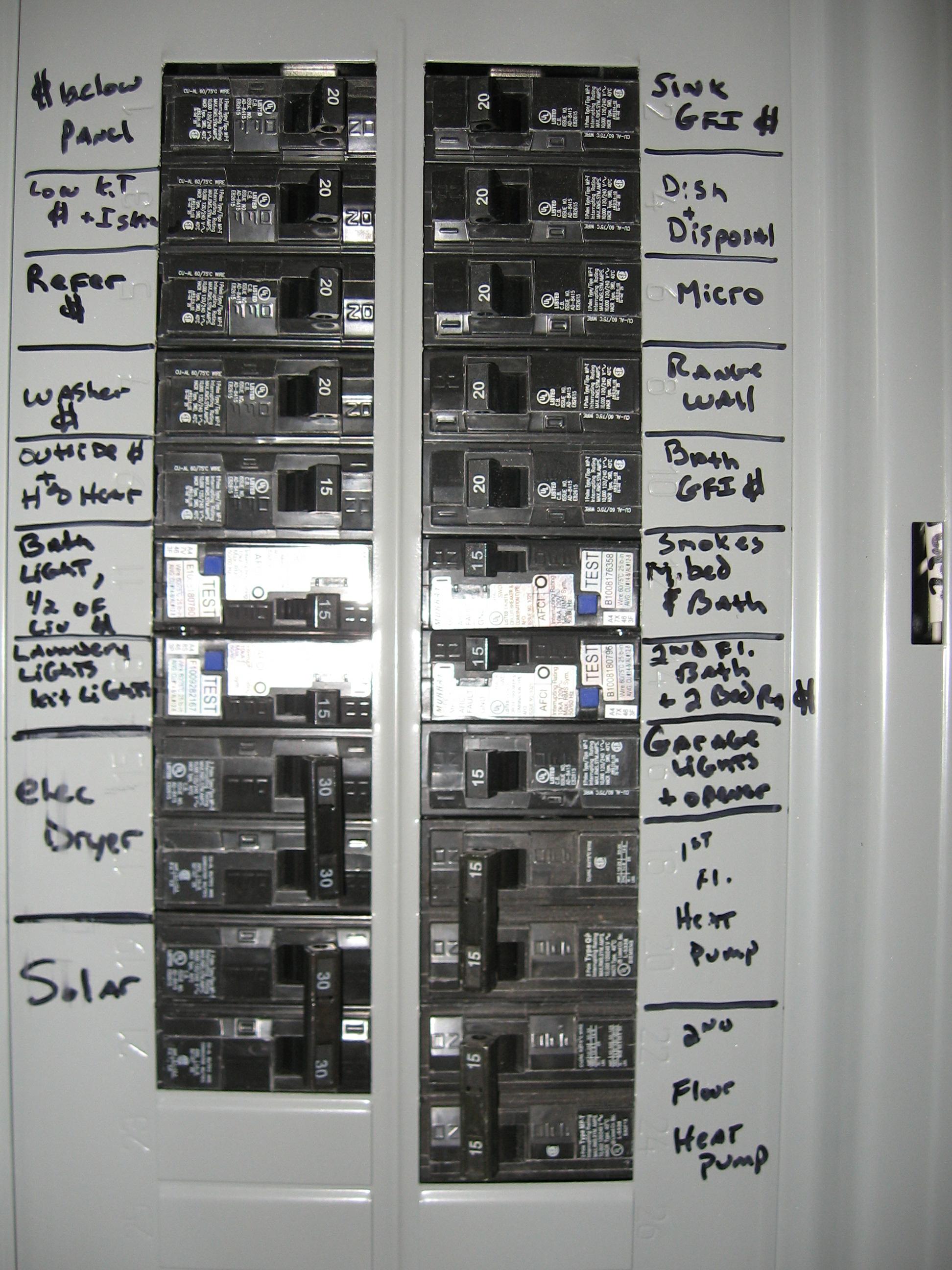

What are the Requirements for Electrical Panel Labeling? The labels that are required for electrical boxes will usually focus on two things. The first is going to be safety related labels. This could be something like a label to indicate how many volts are on a specific breaker, for example. You will also need to have the breakers labeled to indicate what area they will cut power to if turned off.

Complete Guide to Electrical Panel Labels - Metalphoto Of … 25.07.2022 · There are four sets of standards used within the United States that directly address electrical panel labeling in some way. These regulations are monitored and communicated by the Occupational Safety and Health Administration (OSHA), American National Standards Institute (ANSI), National Electrical Code (NEC), and the National Fire Protection Association …

homeinspectioninsider.com › electrical-panelElectrical Panel Location and Installation: Clearance ... May 31, 2021 · Electrical panels need to be installed 4′ off the ground with the center grip handle of the highest circuit breaker is no more than 6’7″ high to be NEC compliant. The clearance around the electric panel must be at least 30 inches wide with 3′ of front workspace clearance.

Step by Step Guide to Labeling Your Electrical Panel — Multi Trade ... The simplest reason to label your electrical panel is that it is an Ontario Electrical Code requirement. The Electrical Safety Authority sets out a clear set of rules and policies to ensure the safety of the public. One of those rules is to have your electrical panel appropriately labeled. What you need to do this yourself

Arc Flash Labeling Requirements | Comply with 2021 NFPA 70E According to NFPA 70E, labeling is required for any piece of electrical equipment that may need examination, adjustment, service or maintenance while energized. These labels communicate the electrical hazards an employee may be exposed to, including the potential for an arc flash incident.

Arc Flash Labeling Requirements | Comply with 2021 NFPA 70E Clarifies that the lockout or tagout program must be either part of the electrical safety program, or must reference the lockout or tagout program. Confirms that electrical safety is based on all equipment being used as intended by the manufacturer. Revises requirements of a lockout device to align with OSHA 1910.333(b)(2)(iii)(E).

NEC 110 Labeling Requirements | Graphic Products Labels are required to be field installed on new equipment The information on the labels must be checked when changes are made Some facilities are exempt from these requirements The first requirement is that labels showing the maximum available fault current be field installed. NEC 110.24 states: Field Marking.

NEC + OSHA Electrical Panel Clearance Requirements 20.04.2021 · One of the most common questions people have when setting standards in a facility for electrical panel clearance requirements is what OSHA says. Fortunately, the OSHA electrical panel clearance requirements are taken directly from the NEC. This means once you understand the NEC panel clearance requirements, you will also know those that OSHA puts …

Electrical Panel / Load Center Age - InspectAPedia We look for an electrical panel brand, model & data tag (usually paper) ... Bryant circuit breakers (Westinghouse) may be identified by product labeling, such as shown on the blue-toggle-switched tandem BR1515 circuit breaker in these illustration (as sold by Amazon in June 2021) As is found on several other circuit breaker manufacturers, the toggle switches on the breakers …

How to Label an Electrical Service Panel | Hunker Assign each circuit breaker a number inside the panel, starting with #1 at the top left. It's best if the number sequence proceeds down the left side to the bottom and continues from the top right to the bottom right. Write each number with a felt tip marker on a 1-inch square sticky label and affix each label next to the breaker it references.

How To Label An Electrical Panel (The Right Way) in Your Tigard Oregon Home 2020 NEC Article 408.4 (A) states: "Every circuit and circuit modification shall be legibly identified as to its clear, evident, and specific purpose or use. The identification shall include an approved degree of detail that allows each circuit to be distinguished from all others.

inspectapedia.com › electric › Electrical-Panel-AgeElectrical Panel / Load Center Age - Electrical Panel Age ... Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com.The firm provides professional HOME INSPECTION SERVICES and also extensive HOME INSPECTION EDUCATION and home inspection-related PUBLICATIONS.

NFPA 70E minimum labeling for panels | Electrician Talk Article 130.5 (C) Equipment Labeling. Electrical equipment such as switchboards, panelboards, industrial control panels, meter socket enclosures, and motor control centers that are likely to require examination, adjustment, servicing, or maintenance while energized shall be field marked with a label containing all the following information:

Standards-based Labelling: The Key to Effective Network Cabling … Standards-based Labelling: The Key to Effective Network Cabling Plan Lin Huanyu Market Development, Regional Manager Brother International Singapore. Measurement tools Infrastructure & standards Cabling Data centre design Software management Tracing and organising Digital Economy Data-driven population Gov. support DATA CENTRE …

› costs › install-electrical-circuit2022 Electrical Panel Upgrade Cost | Cost to Replace an ... Feb 11, 2022 · The cost to relocate an electrical panel starts at around $1,000 but can go as high as $4,000 if a lot of rewiring must be done to accommodate the move. Cost to Rewire an Electrical Panel . Homeowners may not have much insight into whether the wiring of an electrical panel is in poor condition.

Electrical panel labeling requirements osha 9. · Osha requirements stipulate that electrical panels must be accessible at all times for routine maintenance, inspection or emergency service. Electrical safety program chapter 2: Electrical equipment must be correctly strategies for labeling and documentation are partially driven by applicable code requirements .

Electrical panel labeling requirements osha The majority of your electrical safety considerations begin at the breaker panel . Here are some basic safety considerations for all panels : The breaker panel should be readily and easily accessible at all times. Do not store any items on the floor area directly in front of the panel . Maintain an aisle in front of the panel that is at least.

PDF NFPA 70E LABELING REQUIREMENTS - ese-co.com The NFPA 70E Standard provides guidelines for electrical safety in the workplace. This standard has been updated ... The only exception to these new label requirements is to allow labels applied prior to September 30, 2011 to continue to be used if they have the available incidence energy or required PPE listed.

PDF Electrical Electrical Identification Basis of Design Label conduit at all wall penetrations and connections to all panels, junction boxes, and equipment served. 3. Use a black indelible marker and hand print label in a clear workmanlike manner, or use stencil and black paint to provide a clearly legible label. C. Empty conduits 1.

Electrical Panel Compliance with Floor Marking - Graphic Products The width of the space in front of an electrical panel must be the width of the equipment or 30 inches, whichever is wider. The working space must allow for a hinged panel or equipment door to open at a 90° angle. The vertical space must extend from the grade, floor, or platform immediately in front of the electrical panel to either:

Where to Begin? Electrical Control Panel Design Basics 20.11.2019 · Designing the best products requires a well-versed team who is constantly increasing their knowledge base and adapting what they know of electrical control panel design guidelines. With a team of engineers who specializes in control panel design, programming, and integration, it is our job to stay up to day on the latest standards, certifications, and technologies.

What are the Requirements for Labeling Circuit Breakers? If you remove a breaker because it is no longer being used, you need to update the labeling to reflect that. You should not have an empty breaker slot with a label to the side. Instead, that label should be removed or a blank label put over it. Another similar issue is when there is an opening in the box that no longer has wires going through it.

› blog › where-toWhere to Begin? Electrical Control Panel Design Basics Nov 20, 2019 · Designing the best products requires a well-versed team who is constantly increasing their knowledge base and adapting what they know of electrical control panel design guidelines. With a team of engineers who specializes in control panel design, programming, and integration, it is our job to stay up to day on the latest standards ...

› resources › wiring-color-codesWiring Color Codes - NEC Electrical Standards & 3-Phase It’s safe. And, it’s designed to take the guesswork out of electrical work. But it wasn’t always this way. A brief history of wiring color codes. It took until 1928 for wire color coding to make its debut. The National Electrical Code® (NEC) was the first to reference it, and today continues to set the standards for the electrical industry.

› 2021/04/20 › necNEC + OSHA Electrical Panel Clearance Requirements In general, any electrical panel that has 0 to 150 volts going through it needs to have at least 36'' of clearance around it. Panels with 151 to 600 volts should have 42'' of clearance around it. This NEC working clearance will provide not only the person working on the equipment with room, but also their tools.

1910.303 - Occupational Safety and Health Administration Listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling. 1910.303(b)(3) Insulation integrity. Completed wiring installations shall be free from short circuits and from grounds other than those required or permitted by this subpart. 1910.303(b)(4)

How Much Does It Cost to Replace or Upgrade an Electrical Panel… 11.02.2022 · The cost to relocate an electrical panel starts at around $1,000 but can go as high as $4,000 if a lot of rewiring must be done to accommodate the move. Cost to Rewire an Electrical Panel . Homeowners may not have much insight into whether the wiring of an electrical panel is in poor condition. If there is fire damage, melting, or obvious ...

Post a Comment for "44 electrical panel labeling standards"